Definition of middle management's role

The middle manager's role in a company is connecting the top-level staff with the lower-level ones. They translate the strategy developed by the executive team into achievable department goals. They also collect data and present results to the executive group. Their responsibilities range from making decisions on the allocation of resources to overseeing the work of subordinates.

Federal government middle managers are in similar or higher supervisory positions to front-line supervisors. Their duties include establishing policies and guidelines that govern the work of lower-level employees.

The challenges faced by middle managers

Many middle managers are faced with conflicting roles which can cause frustration. These managers have to manage subordinates as well as reporting to higher-ups. They also have to enforce policies, which may be contrary to their direct reports. Fortunately, technology can help middle managers cope with this dilemma. For example, the PwC app identifies digital training opportunities and guides managers to over 300 courses.

The middle managers need to be able understand all parties and establish a relationship of trust between them. This can be hard because they are often limited in time due to multiple stakeholders. They need to prioritise their tasks and ensure that every need is met.

Tools to help middle managers collaborate

Middle managers play a critical role in organizations. Their main job is to keep track of project progress, move information among teams, and act as a liaison between junior employees and senior leaders. But communication is more difficult when working remotely. There are many tools that help middle managers to collaborate more effectively.

Many middle managers are required to attend a lot of meetings. This can consume up to 35%. Because of this, middle managers often have very little time to do any other work. They also have a high cognitive burden due to video communications. This can lead to burnout.

Communication skills

A middle manager's success depends on his or her ability to communicate clearly. These professionals are required to communicate clearly with their senior managers and staff. The ability to communicate effectively can improve trust and engagement with colleagues, as well as their performance and influence.

Communication skills in middle management can be crucial in any industry. Middle managers interact directly with employees, unlike most senior administrators. This means that they must be able to communicate effectively verbally and in writing. It is essential for middle managers to learn to write clearly and effectively, to avoid miscommunication, and to avoid errors.

FAQ

What kind of people use Six Sigma

Six sigma is a common concept for people who have worked in statistics or operations research. Anybody involved in any aspect or business can benefit.

It is a commitment-intensive task that requires strong leadership skills.

What is the best way to motivate your employees as a manager?

Motivation is the desire to do well.

It is possible to be motivated by doing something you enjoy.

You can also get motivated by seeing your contribution to the success or the improvement of the organization.

For example, if you want to become a doctor, you'll probably find it more motivating to see patients than to study medicine books all day.

A different type of motivation comes directly from the inside.

You may feel strongly that you are responsible to help others.

Perhaps you enjoy working hard.

Ask yourself why you feel so motivated.

Then, consider ways you could improve your motivation.

What's the difference between leadership & management?

Leadership is all about influencing others. Management is about controlling others.

Leaders inspire followers, while managers direct workers.

A leader motivates people to achieve success; a manager keeps workers on task.

A leader develops people; a manager manages people.

What is Six Sigma, exactly?

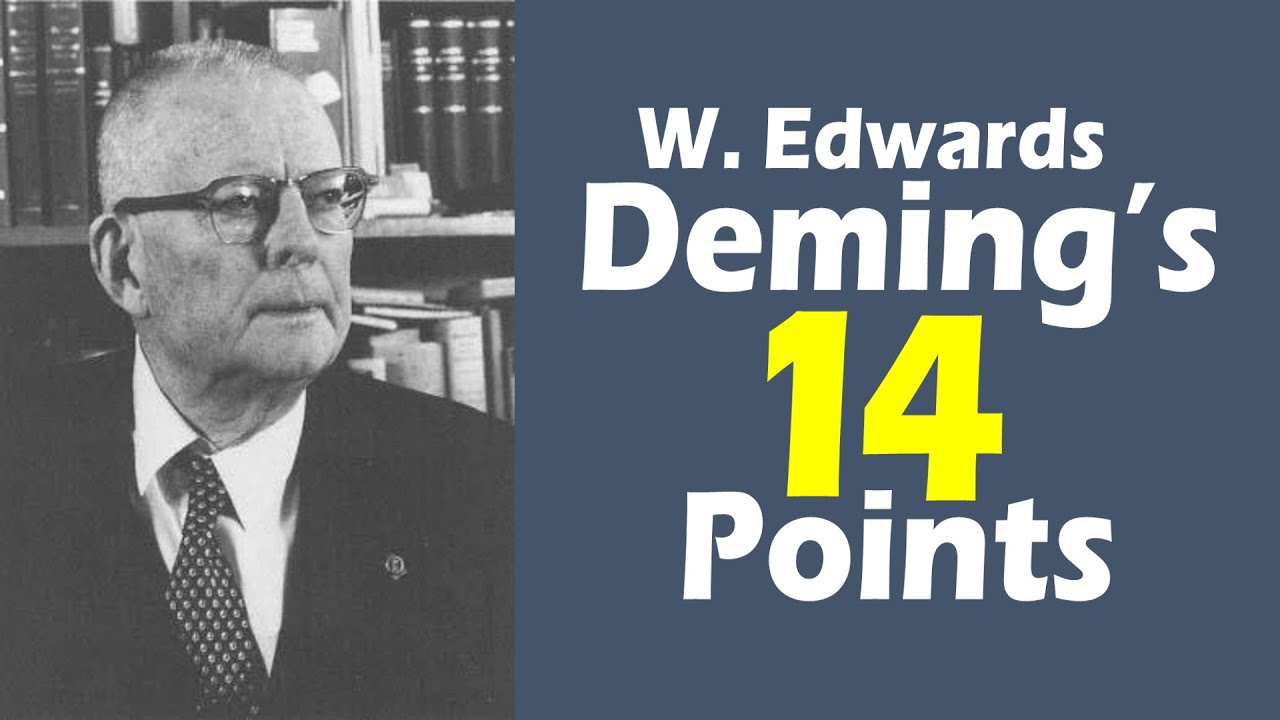

It's a strategy for quality improvement that emphasizes customer care and continuous learning. It is a method that eliminates defects using statistical techniques.

Motorola developed Six Sigma in 1986 to help improve its manufacturing processes.

The idea quickly spread in the industry. Many organizations today use six-sigma methods to improve product design and production, delivery and customer service.

What role does a manager have in a company's success?

Different industries have different roles for managers.

In general, a manager controls the day-to-day operations of a company.

He/she is responsible for ensuring that the company meets all its financial obligations and produces the goods or services customers want.

He/she ensures that employees follow the rules and regulations and adhere to quality standards.

He/she oversees marketing campaigns and plans new products.

Statistics

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

External Links

How To

How is Lean Manufacturing done?

Lean Manufacturing processes are used to reduce waste and improve efficiency through structured methods. They were developed by Toyota Motor Corporation in Japan during the 1980s. The aim was to produce better quality products at lower costs. Lean manufacturing emphasizes removing unnecessary steps from the production process. It has five components: continuous improvement and pull systems; just-in time; continuous change; and kaizen (continuous innovation). Pull systems involve producing only what the customer wants without any extra work. Continuous improvement is the continuous improvement of existing processes. Just-in-time is when components and other materials are delivered at their destination in a timely manner. Kaizen means continuous improvement, which is achieved by implementing small changes continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. These five elements are used together to ensure the best possible results.

Lean Production System

Six key concepts are the basis of lean production:

-

Flow - focus on moving material and information as close to customers as possible;

-

Value stream mapping - break down each stage of a process into discrete tasks and create a flowchart of the entire process;

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban is a visual system that uses visual cues like stickers, colored tape or stickers to keep track and monitor inventory.

-

Theory of constraints: identify bottlenecks in your process and eliminate them using lean tools, such as kanban board.

-

Just-in-time - deliver components and materials directly to the point of use;

-

Continuous improvement - incremental improvements are made to the process, not a complete overhaul.